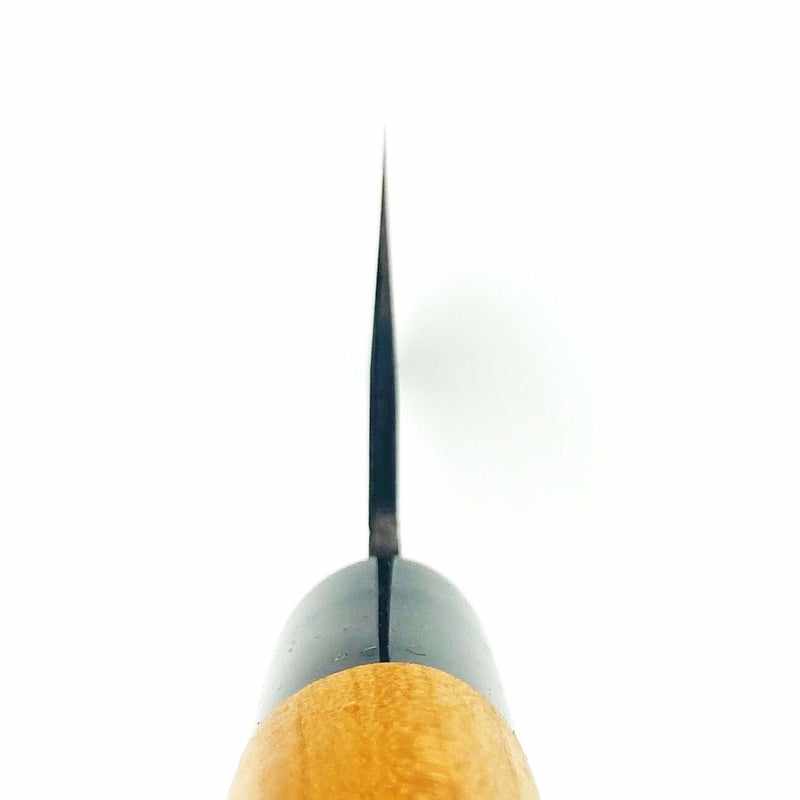

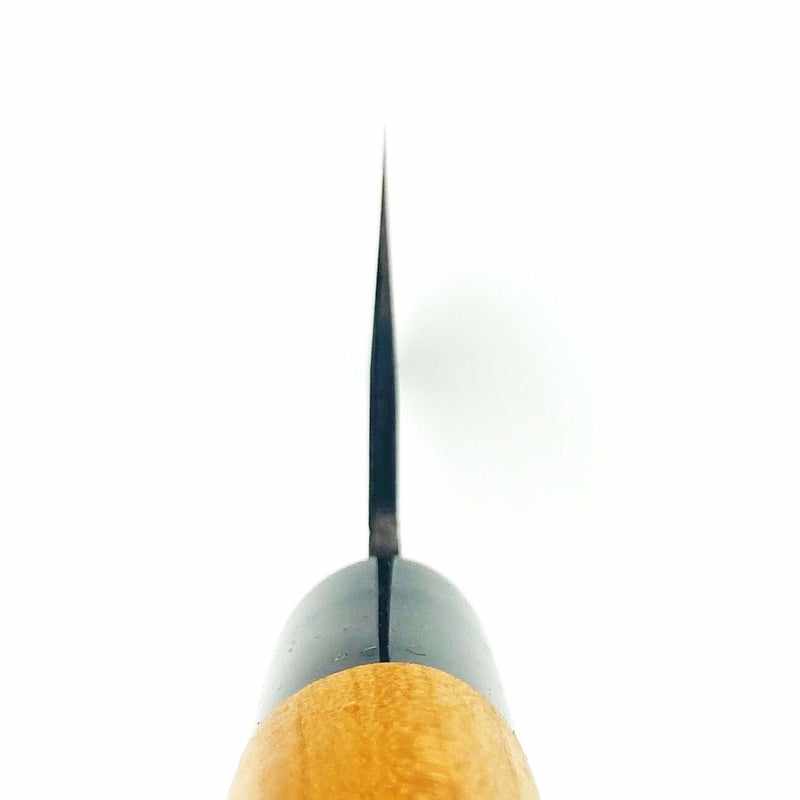

Yukihiro Sakai Hinokuni White #1 Kurouchi 240mm Nakiri

Tax excluded. Shipping calculated at checkout

We take responsibility for getting the perfect knife to your door in good condition.

FREE SHIPPING in the United States on orders over $99. Orders are typically fulfilled within 2 business days, with shipping times varying by destination.

Each package has full insurance on every item.

Yukihiro Sakai is a young blacksmith trained under Nishida-san of Nishida Knives. With his expertise in working with one of the purest forms of fine-grain high-carbon steels (White Steel #1), he has crafted his own handmade knives.

Very few blacksmiths create their own crafting materials, but Yukihiro-san does. He puts in laborious work because he believes it makes a difference in the end product. He understands the importance of proper technique to limit carbon migration from the core steel to the iron cladding. These are the same principles that have made Takeda and Moritaka Hamono famous.

Yukihiro Sakai uses White (Shirogami) Steel #1 for his kitchen knives. While White #1 is highly reactive, it is unmatched for its sharpness.

These knives are hefty, forward heavy, and definitely a workhorse grind.

Why not is the type of answer you'll often get when asking a Japanese person why something is done in a certain way. So we say, why not a 240mm nakiri! A nakiri will quickly become your go-to vegetable prep knife. The flat surface along the length of the cutting edge means you can say goodbye to accordion cuts. At this length, you can easily rock chop too. Just anchor down that tip, 240mm away from the butt, and rock away.

- Steel Type: Shirogami #1 Carbon Steel

- Knife Type: Nakiri

- Steel Grade: Shirogami #1

- Hardness (Rockwell HRC): 62

- Blade Height: 56 mm

- Blade Finish: Kurouchi

- Origin of Steel: Japan

- Blade Length: 240 mm

- Total Length: 380 mm

- Blade Thickness (heel): 3 mm

- Blade Thickness (center): 2 mm

- Blade Thickness (1 cm from tip): 1 mm

Tokushu's Guarantee

We take full responsibility for ensuring your knife arrives safely and in perfect condition. If you experience any shipping delays, damage, or other issues, don’t worry—we’ve got you covered. Contact us, and we’ll handle everything until your knife is in your hands.

Insured and Protected

We provide shipping insurance on every order for your peace of mind. If your package is lost or not delivered, we handle the claim process to secure a refund or replacement for you.

For assistance, contact us at Tony@Tokushuknife.com.

Shipping information

FREE SHIPPING in the United States on orders over $99. Orders are typically fulfilled within 2 business days, with shipping times of 1 - 5 business days via UPS Ground.

For international orders, we ship via UPS - DDP (Duties Paid), meaning all customs duties, taxes, and VAT are included in the product price for a smooth, hassle-free delivery. Shipping times vary by destination and are in addition to our 2-business-day fulfillment period.

Need help? We handle all shipping issues, including lost packages and claims—contact us at Tony@Tokushuknife.com for support!

Choose options

Cut Above the Rest

Built to Last

The high-grade steel we use is carefully selected and forged using techniques that have been proven over centuries. These knives aren’t just sharp – they’re built to stay that way through years of daily use. Plus, they develop a beautiful patina over time that tells the story of your cooking journey.

Need help?

Frequently Asked Questions

Order

We take full responsibility for ensuring your knife arrives safely and in perfect condition. If you experience any shipping delays, damage, or other issues, don’t worry - we’ve got you covered. Contact us, and we’ll handle everything until your knife is in your hands.

We provide shipping insurance on every order for your peace of mind. If your package is lost or not delivered, we handle the claim process to secure a refund or replacement for you.

For assistance, contact us at Tony@Tokushuknife.com.

FREE SHIPPING in the United States on orders over $99. Orders are typically fulfilled within 2 business days, with shipping times of 1 - 5 business days via UPS Ground.

For international orders, we ship via UPS - DDP (Duties Paid), meaning all customs duties, taxes, and VAT are included in the product price for a smooth, hassle-free delivery. Shipping times vary by destination and are in addition to our 2-business-day fulfillment period.

Need help? We handle all shipping issues, including lost packages and claims—contact us at Tony@Tokushuknife.com for support!

Level up with a set

For a custom consultation to build your perfect knife contact Tony directly at Tony@Tokushuknife.com

Carter Cutlery Muteki #5529 Funayuki 190mm 7.48" by Taylor Shields

This Muteki Funayuki kitchen knife by Taylor Shields offers exceptional performance with its Hitachi White #1 steel core laminated with 410 stainless steel for superior sharpness and durability. The handle, made from Thuya and Leopardwood, is complemented by white and Tiffany blue G10 liners, providing a unique and elegant touch. Perfect for a wide range of kitchen tasks, this knife is as functional as it is beautiful.

Specifications:

- Style: Muteki, Funayuki Kitchen Knife

- Blade Steel: Hitachi White #1 Steel Core, Laminated with 410 Stainless Steel

- Finish: Forged/Polished

- Handle: Thuya, Leopardwood

- Liner: White G10, Tiffany Blue G10

- Blade Length: 7.48″ (190 mm, 6.27 sun)

- Blade Thickness: 0.082″ (2.09 mm)

- Blade Width: 1.81″ (46 mm)

- Weight: 4.87 oz (138 g)

- Maker: Taylor Shields

- Brand: Muteki

- Knife Type: Kitchen Knife

- Kitchen Knife Style: Funayuki

- Steel: White/Stainless

- Steel Finish: Forged/Polished

- Handle Material: Thuya, Leopardwood with G10 liners

- Weight Range: 4-4.99 oz